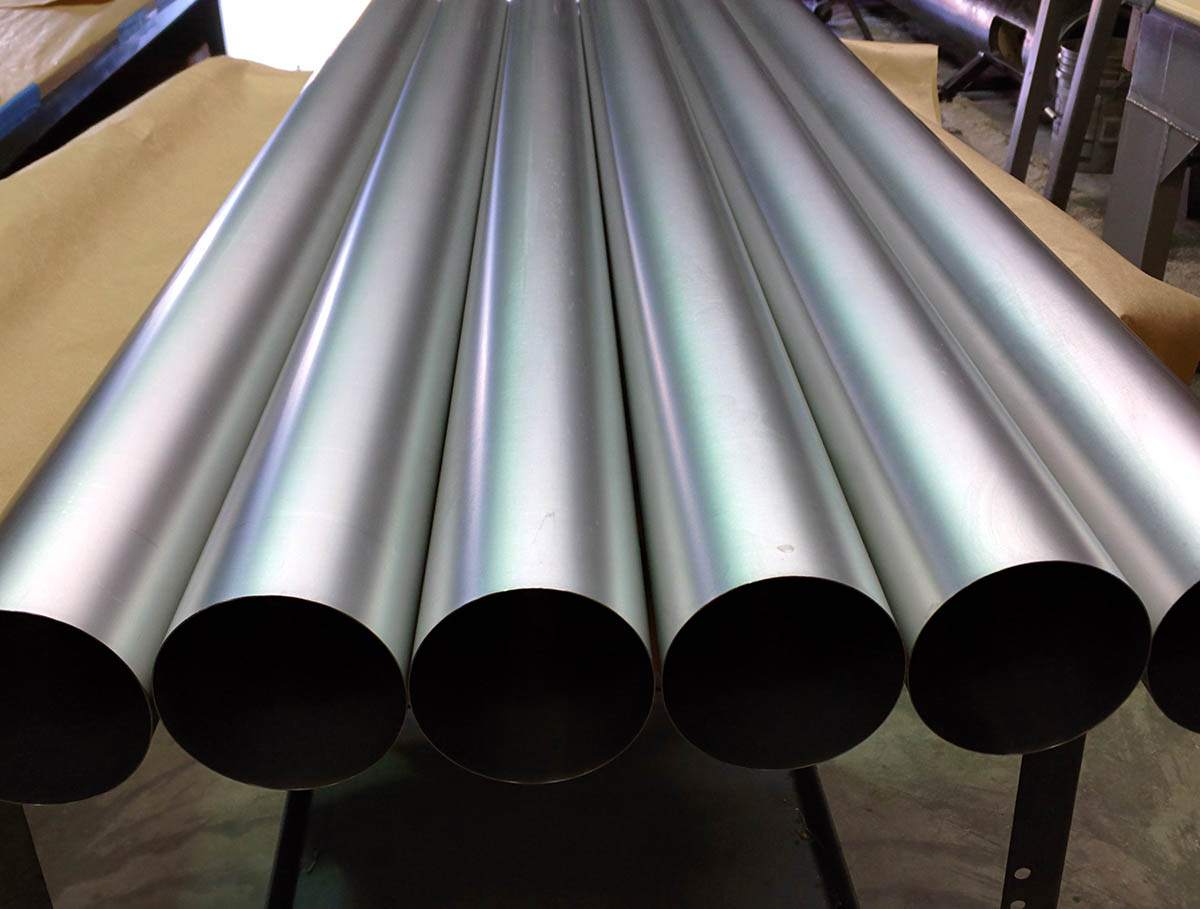

Tubing

Custom Tube and Manufacturing Incorporated has been manufacturing precision seamless high temperature superalloy tubing for over 40 years.

Custom Tube and Manufacturing Incorporated has been manufacturing precision seamless high temperature superalloy tubing for over 40 years.

Our tubing is utilized in the nuclear, aerospace, cryogenic, medical, down hole exploration, and military industries.

All tubing production starts on manual tube drawing machines, which translates into the highest quality tubing. Cold forming is the only method of tube drawing we use; which yields the best grain structure and tightest tolerances; as well as the ability to produce cold strengthened tubing such as

MP35N. Inconel 718 per AMS 5589 and AMS 5590, Inconel 625 per AMS 5581, and also Hastelloy X per AMS 5587 are just a few examples of cold-drawn tubing commonly manufactured by Custom Tube and Manufacturing Incorporated. Each tube is handled and inspected many times during the drawing process. During the heat treating process tubes are handled with white gloves.

The combination of our machine shop and tube drawing department gives us the ability to make an array of complex parts. All testing is performed by an independent metallurgical laboratory that is ISO, ANSI, and NADCAP certified among many other accreditation.

Custom shaped tubing that has specific design features is our specialty.

We combine tube making technology with precision machine work to make this possible all in one place, thus providing a one stop shop. Our cold-formed custom shaped tubing produces extremely consistent and tight tolerance shaped tubing used commonly for medical cannulas and military defense components.

Custom Swaged Tubing

With the use of our 2 rotary swaging machines with a capacity ranging from .150″ diameter to 3.25″ diameter we can create very intricate parts such as landing gear shocks and swaged struts for aerospace.

- When you call for a quote, we will immediately design the procedure for producing your custom tubing.

- Our current capacity is up to 3.250″ OD and as thin as .008″ wall thickness depending upon diameter.

- Our maximum length on one piece is 12 feet, however we do not have a maximum total footage.

- We have no minimum footage requirements. We will produce the exact amount of tubing you require even if it’s only 10 feet.

Seamless Inconel 718 3.200” OD x .022” Wall x 5’ Long AMS 5589

Picture is from one end of tube looking through to demonstrate mirror like finish and quality of tubing.